Short Description

1,

Shuttle mover, working in combination with radio shuttle, is a fully

automatic and high density storage system, consists of shuttle mover,

radio shuttle, racking, shuttle mover lifter, pallet convey system, WCS,

WMS and so on.

2,

Shuttle mover system is widely used in different industries, such as

garment, food and beverage, automobile, cold chain, tobacco, electricity

and so on.

.

Product Details

Product Analysis:

①Functions

1 | Pallet conveying | Independent pallet conveying capability, shuttle mover and radio shuttle work individually in fast operation. |

2 | Charging online | Multi-level power threshold control, self-judging and self-charging on line. |

3 | Remote control | One press to switch online and manual operation on remote control mode (optional) |

4 | System monitoring | Monitoring system data in real time and alarm in sound and light in abnormal status |

5 | Heartbeat function | Communicate to host computer control system in real time by heartbeat check, monitoring online status. |

6 | Remote function | It is capable of updating and downloading program remotely (In Wi-Fi Network) |

7 | Emergency Stop | Press button of emergency stop or release emergency stop signal by control system. Accepting emergency stop instruction, shuttle stops instantly until emergency lifted. It is capable of guaranteeing device or goods stop safely in maximal deceleration when it executes this instruction |

②What kind of goods are suitable for Shuttle Mover Storage System ?

Goods package type: | Pallet |

Goods dimension(mm): | W1200xD1000mm;W1200xD1200mm;W1400xD1200mm;W1000xD1100mm;W1200xD1200mm. |

Goods weight: | <=1500kg |

Operation height | <=15m |

③Features

Ø Barcode site recognition, accurate positioning and safe work.

Ø Able to board radio shuttle and convey pallet.

Ø Fully automatically unmanned batch work in 24 hours.

Ø Able to charge radio shuttle online in operation.

Ø Both FIFO and FILO could achievable.

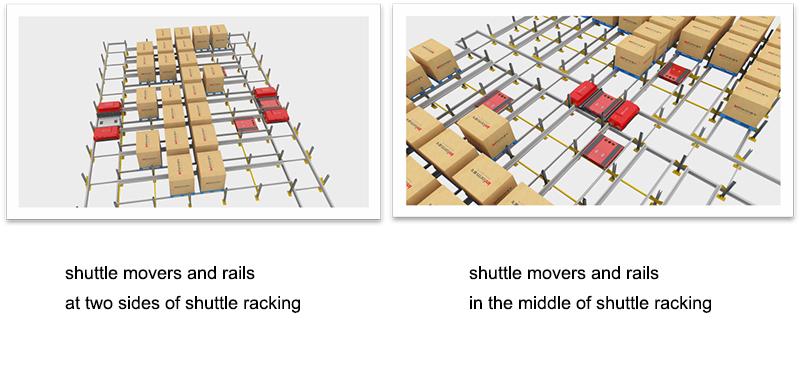

④Operation Type

Sub-lane

as storage unit and main lane as conveying path, it autonomously stores

and retrieves goods and could be different as arrangement on two sides

and arrangement in middle.

◆Arrange shuttle movers and rails at two sides of shuttle racking

· Operation mode of radio shuttle: FIFO

· In/Out mode: inbound on one side and outbound on the other side

◆Arrange shuttle movers and rails in the middle of shuttle racking

· Operation mode of radio shuttle: FILO

· In/Out mode: inbound and outbound both on one side

⑤Design, Test &Warranty

Design

Free design could be provided with the following information.

Ø Warehouse storage area Length____mm x Width____mm x Clear height___mm.

Ø Warehouse’s door position for loading and unloading goods.

Ø Pallet Length____mm x Width____mm x Height___mm x Weight_____kg.

Ø Warehouse Temperature_____Degrees Celsius

Ø Inbound and outbound efficiency: Quantity of pallets per hour_____

Test

Shuttle mover will be tested before delivery. Engineer will test the whole system on-site or online.

Warranty

Warranty

is one year. Fast response within 24 hours for overseas customer.

Firstly test online and adjust ,if couldn’t repair online , engineer

will go and solve the problems on site. Free spare parts will be

supplied during the warranty time.

Project cases:

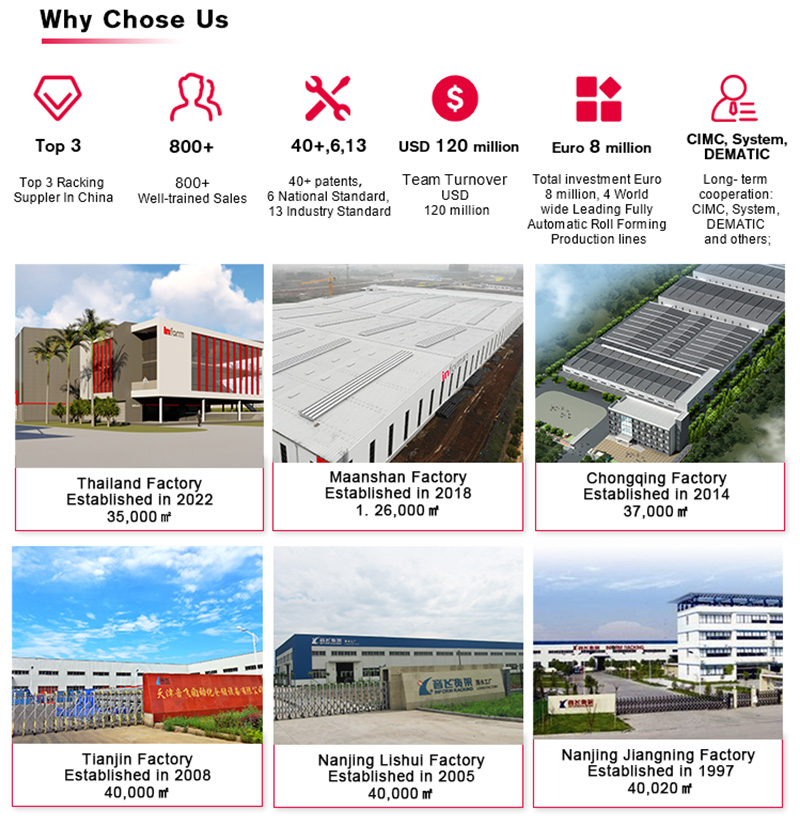

Why choose us?

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed state controlled enterprise, specialized in the logistic storage solution field since 1997.( 27 years of experience)

2.Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3.Inform owns 6 factories, with over 1000 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry.

Q1: What’s your trading terms?

1) Payment terms: As general, T/T 30% deposit after order confirmed, 70% balance paid against BL. L/C also available.

2) Shipping port: Shanghai / Nanjing port China.

3) Discounts: we will offer the biggest discount for large quantity.

Q2: Are you a factory or trading company?

A:We are factory and have 5 factories.We’ve been in the market of logistic storage solutionssince 1997.We design,manufacture racking and assemble shuttle, four-way shuttle etc by ourselves.

Q3: Do you have OEM products to sell?

A:Yes.Both OEM and ODM are available .

Q4:Do you have the minimum order requirements?

A:Any quantity and customized design is acceptable.

Q5:Are samples available?

A:Yes. Short sections of samples can be provided for free, but the international transportation will be at the customers’ expense.

Q6:What’s the delivery time?

A:It depends on the order quantity and racking types. Generally speaking, for the standard pallet racking, it will be within 20 days.

Short Description

1,

Shuttle mover, working in combination with radio shuttle, is a fully

automatic and high density storage system, consists of shuttle mover,

radio shuttle, racking, shuttle mover lifter, pallet convey system, WCS,

WMS and so on.

2,

Shuttle mover system is widely used in different industries, such as

garment, food and beverage, automobile, cold chain, tobacco, electricity

and so on.

.

Product Details

Product Analysis:

①Functions

1 | Pallet conveying | Independent pallet conveying capability, shuttle mover and radio shuttle work individually in fast operation. |

2 | Charging online | Multi-level power threshold control, self-judging and self-charging on line. |

3 | Remote control | One press to switch online and manual operation on remote control mode (optional) |

4 | System monitoring | Monitoring system data in real time and alarm in sound and light in abnormal status |

5 | Heartbeat function | Communicate to host computer control system in real time by heartbeat check, monitoring online status. |

6 | Remote function | It is capable of updating and downloading program remotely (In Wi-Fi Network) |

7 | Emergency Stop | Press button of emergency stop or release emergency stop signal by control system. Accepting emergency stop instruction, shuttle stops instantly until emergency lifted. It is capable of guaranteeing device or goods stop safely in maximal deceleration when it executes this instruction |

②What kind of goods are suitable for Shuttle Mover Storage System ?

Goods package type: | Pallet |

Goods dimension(mm): | W1200xD1000mm;W1200xD1200mm;W1400xD1200mm;W1000xD1100mm;W1200xD1200mm. |

Goods weight: | <=1500kg |

Operation height | <=15m |

③Features

Ø Barcode site recognition, accurate positioning and safe work.

Ø Able to board radio shuttle and convey pallet.

Ø Fully automatically unmanned batch work in 24 hours.

Ø Able to charge radio shuttle online in operation.

Ø Both FIFO and FILO could achievable.

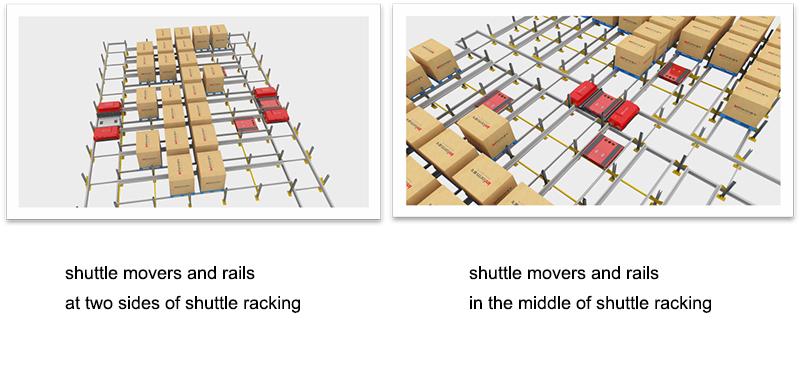

④Operation Type

Sub-lane

as storage unit and main lane as conveying path, it autonomously stores

and retrieves goods and could be different as arrangement on two sides

and arrangement in middle.

◆Arrange shuttle movers and rails at two sides of shuttle racking

· Operation mode of radio shuttle: FIFO

· In/Out mode: inbound on one side and outbound on the other side

◆Arrange shuttle movers and rails in the middle of shuttle racking

· Operation mode of radio shuttle: FILO

· In/Out mode: inbound and outbound both on one side

⑤Design, Test &Warranty

Design

Free design could be provided with the following information.

Ø Warehouse storage area Length____mm x Width____mm x Clear height___mm.

Ø Warehouse’s door position for loading and unloading goods.

Ø Pallet Length____mm x Width____mm x Height___mm x Weight_____kg.

Ø Warehouse Temperature_____Degrees Celsius

Ø Inbound and outbound efficiency: Quantity of pallets per hour_____

Test

Shuttle mover will be tested before delivery. Engineer will test the whole system on-site or online.

Warranty

Warranty

is one year. Fast response within 24 hours for overseas customer.

Firstly test online and adjust ,if couldn’t repair online , engineer

will go and solve the problems on site. Free spare parts will be

supplied during the warranty time.

Project cases:

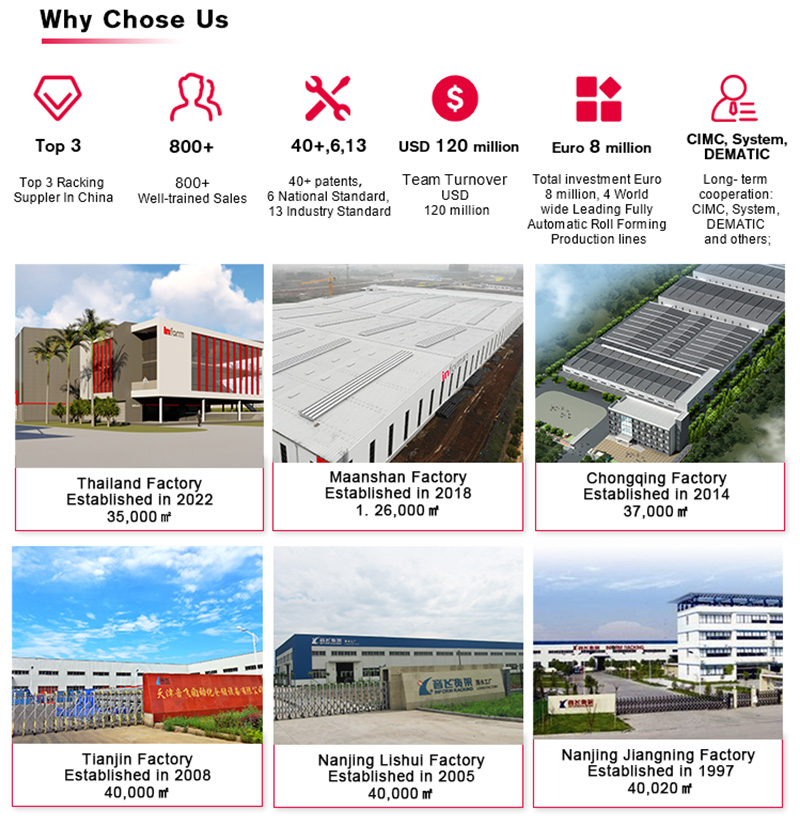

Why choose us?

Top 3 Racking Suppler In China

The Only One A-share Listed Racking Manufacturer

1. NanJing Inform Storage Equipment Group,as a public listed state controlled enterprise, specialized in the logistic storage solution field since 1997.( 27 years of experience)

2.Core Business: Racking

Strategic Business:Automatic System Integration

Growing Business: Warehouse Operation Service

3.Inform owns 6 factories, with over 1000 employees. Inform listed A-share on June 11, 2015, stock code: 603066, becoming the first listed company in China’s warehousing industry.

Q1: What’s your trading terms?

1) Payment terms: As general, T/T 30% deposit after order confirmed, 70% balance paid against BL. L/C also available.

2) Shipping port: Shanghai / Nanjing port China.

3) Discounts: we will offer the biggest discount for large quantity.

Q2: Are you a factory or trading company?

A:We are factory and have 5 factories.We’ve been in the market of logistic storage solutionssince 1997.We design,manufacture racking and assemble shuttle, four-way shuttle etc by ourselves.

Q3: Do you have OEM products to sell?

A:Yes.Both OEM and ODM are available .

Q4:Do you have the minimum order requirements?

A:Any quantity and customized design is acceptable.

Q5:Are samples available?

A:Yes. Short sections of samples can be provided for free, but the international transportation will be at the customers’ expense.

Q6:What’s the delivery time?

A:It depends on the order quantity and racking types. Generally speaking, for the standard pallet racking, it will be within 20 days.